- 1. Why does a cosmetic QC room require specialized lighting?

- 2. Key considerations when selecting lights for cosmetic QC rooms

- 3. Recommended lighting types for cosmetic QC rooms

- 4. Technical Considerations and Compliance When Installing Lighting in a Cosmetic QC Room

- 5. Recommended Lighting Types for Different Areas in a Cosmetic QC Room

- 6. About Lighting in Cosmetic QC Rooms

- 7. Need Expert Guidance for Lighting Your Cosmetic QC Room?

1. Why does a cosmetic QC room require specialized lighting?

In the cosmetics industry, where color, texture, and product clarity play a critical role in ensuring quality, lighting is not just a supporting factor—it is a mandatory condition. The lighting system in a Quality Control (QC) room must be specially designed to meet strict requirements for visual accuracy and international standards.

Lighting directly affects sensory evaluation

During inspection of cosmetic products such as creams, lipsticks, or foundation, lighting plays a decisive role in assessing:

- Color: Under improper color temperature or low CRI lighting, product colors may appear distorted, leading to errors in testing or post-production quality control.

- Clarity and uniformity: Products like gels, serums, or emulsions require uniform and sufficient lighting to detect impurities, bubbles, or precipitation.

- Texture and reflectivity: Evaluating smoothness, shine, and consistency also demands accurate and stable lighting.

If the lighting system does not meet standards, sensory assessments become inconsistent, which could lead to unnecessary product rejection—or worse, defective products reaching the market.

Lighting impacts analytical and instrument accuracy

Beyond visual checks, many analytical devices in the QC room (e.g., chromatography, color meters, turbidity meters) also require a stable lighting environment for accurate calibration. Flickering, overly bright, or color-shifted light can significantly increase measurement errors.

Regulations in ISO 22716 and Cosmetic GMP

Quality management standards in cosmetics—especially ISO 22716 (Good Manufacturing Practices - GMP)—have clear requirements for lighting systems:

- ISO 22716 - Section 3.2: Production facilities must have sufficient lighting appropriate for each functional area to ensure proper observation during all inspection processes.

- Cosmetic GMP: Requires lighting to be flicker-free, anti-glare, and not cause color distortion during visual assessments.

Furthermore, inspection teams from agencies such as the FDA, ASEAN Cosmetic Directive, or ISO certifiers may also request periodic lux level validation reports to ensure lighting meets required standards.

In summary: A specialized lighting system that meets ISO standards and supports accurate sensory assessment helps cosmetic QC rooms:

- Improve accuracy in product evaluation

- Comply with international quality and audit standards

- Avoid risks caused by misjudgment or measurement errors

2. Key considerations when selecting lights for cosmetic QC rooms

Lighting for QC (Quality Control) rooms cannot be selected as casually as for offices or residential spaces. This environment demands high sensory accuracy, directly impacting the visual inspection of color, clarity, and texture. Here are four critical technical factors to consider when choosing the right lighting:

1. Color Temperature (Kelvin): 4000K-5000K recommended

Color temperature determines the "shade" of light: warm - neutral - cool.

- Warm light (<3500K) casts a yellowish tone, distorting actual product colors.

- Cool light (>6000K) creates a pale bluish effect, lacking natural balance.

Ideal solution: Choose LED lights with 4000K-5000K, equivalent to natural daylight. This range best reproduces product colors in the QC environment.

2. Color Rendering Index (CRI): 90 or higher

CRI measures how accurately lighting reproduces the colors of objects. It ranges from 0 to 100.

- CRI < 80: Likely to cause color deviation, problematic for inspecting lipsticks, blush, or gels.

- CRI 90+: Enables precise color differentiation, ideal for cosmetics QC.

In cosmetic QC rooms, a minimum CRI of 90 is required, preferably using specialized cleanroom lighting with verified optical standards.

3. Illuminance (Lux): 500-1000 Lux depending on area

Illuminance measures the amount of light per surface area, in Lux. This is crucial for appropriate lighting distribution:

|

QC Area |

Recommended Illuminance |

|

Sensory inspection |

800-1000 Lux |

|

Sample preparation |

600-800 Lux |

|

QC office area |

500-600 Lux |

Use a lux meter to verify actual lighting levels after installation, ensuring uniform distribution without dark spots or glare.

4. Anti-glare, flicker-free lighting design

Good lighting is not only about correct color and intensity—it must also be stable and eye-friendly for operators.

- Flickering lights cause eye strain and reduce accuracy over extended use.

- Glare can obscure product details and compromise evaluation.

Solution: Use anti-glare LED panels with stable drivers and certified flicker-free performance, designed for cleanroom and QC environments.

3. Recommended lighting types for cosmetic QC rooms

Not all lighting types are suitable for QC environments in the cosmetics industry. Using the wrong light may lead to sensory inaccuracies, increased rework costs, or flawed quality evaluations.

Here are 3 lighting types recommended for cosmetic QC rooms—each suited to specific functions:

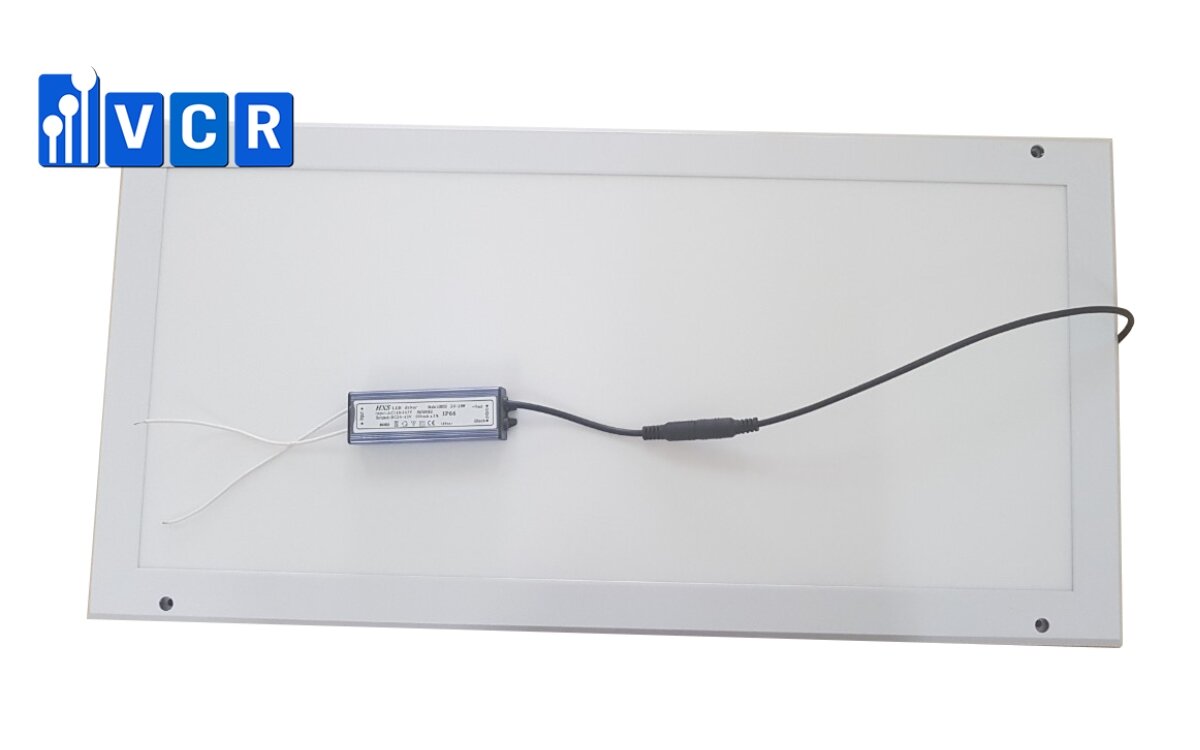

1. LED Panel - General, uniform lighting

|

Technical Specification |

Recommended Value |

|

Color Temperature |

4000K - 5000K |

|

CRI |

≥ 90 |

|

Illuminance |

600-800 Lux |

|

Design |

Recessed mount, dustproof |

Key Advantages:

- Even light distribution without dark spots

- Flat design, easy to clean, cleanroom-compatible

- Stable operation, flicker-free

Recommended Use: Install in main QC work areas for general sample handling and inspections.

2. LED Tube (T8) - Flexible and cost-effective

|

Technical Specification |

Recommended Value |

|

Color Temperature |

4000K - 4500K |

|

CRI |

85-90 |

|

Illuminance |

500-600 Lux |

|

Design |

Replaceable tube fixture |

Key Advantages:

- Low investment, easy to maintain

- Individual tube replacement possible

- Ideal for supplemental lighting zones

Recommended Use: Install in secondary work zones, hallways, or low-priority areas in the QC room.

3. High CRI Color Viewing Lamp - For precise sensory evaluation

|

Technical Specification |

Recommended Value |

|

Color Temperature |

~5000K |

|

CRI |

≥ 95 |

|

Design |

Spot or table lamp |

Key Advantages:

- Simulates natural daylight for color matching

- Highlights subtle shade variations—ideal for color cosmetics

- Adjustable beam angle for better accuracy

Recommended Use: Use in color inspection or sample viewing areas, especially for products like lipstick, blush, or foundation that demand strict color consistency.

4. Technical Considerations and Compliance When Installing Lighting in a Cosmetic QC Room

Choosing the right type of lighting is not enough; the installation and operation of the lighting system in a QC room must adhere to strict technical requirements to ensure lighting effectiveness, safety, and compliance with GMP/ISO standards. Below are three essential principles to follow when implementing lighting in a cosmetics quality control environment:

Avoid wall-mounted or angled lighting

In a QC environment, lighting should be evenly distributed and directed straight down from above to the workspace, avoiding uneven areas of light and shadow.

- Fixtures such as wall-washer lights, angled spotlights, or side-mounted lights can cause perceptual distortion.

- Side lighting can obscure critical details, increasing the risk of overlooking product flaws.

Technical requirement: Only use recessed LED panels or ceiling-mounted tube lighting that casts illumination from overhead.

All lighting fixtures must meet IP65 rating or higher

Cleanrooms and QC rooms require strict hygiene standards. Dust, insects, or moisture must not infiltrate lighting fixtures.

|

Criteria |

Minimum Requirement |

|

Ingress Protection (IP) |

IP65 (dust sealed + water resistant) |

|

Construction |

Fully enclosed, no gaps |

|

Insect protection |

Rubber gaskets or fine mesh present |

Fixtures not meeting IP65 standards may become contaminated, compromising inspection quality, and may be rejected during GMP audits.

Periodic illuminance checks using a lux meter

Light output can diminish over time due to dust, LED aging, or malfunction. Periodic checks are necessary to ensure that illuminance remains within acceptable standards.

- Measurement tool: Lux meter

- Recommended frequency: Every six months or whenever lighting fixtures are replaced or adjusted

- Documentation: Record and store measurement logs as part of GMP-compliant records

Some manufacturers also conduct periodic sensory evaluations to recalibrate lighting as needed.

5. Recommended Lighting Types for Different Areas in a Cosmetic QC Room

A cosmetic QC room within a manufacturing facility typically comprises various functional zones—each requiring specific lighting conditions. Choosing lighting suited to each functional context enhances both cost-efficiency and testing effectiveness.

Below is a table suggesting appropriate lighting types for each QC area:

|

Area |

Recommended Lighting Type |

Technical Requirements |

|

Sample Analysis |

Ceiling-mounted LED Panel |

CRI ≥ 90, Illuminance ≥ 800 Lux |

|

Sensory Evaluation |

High-CRI color viewing lamp (spot or desk mount) |

CRI ≥ 95, daylight-like ~5000K |

|

Sample Preparation |

LED Tube (T8) fixture |

CRI ≥ 85, neutral light 4000-4500K, ≥ 600 Lux |

|

QC Office Area |

Anti-glare LED with dimmer capability |

CRI ≥ 80, soft light without flicker |

Sample Analysis Zone — Stable and accurate lighting

This is the primary work area in the QC room, where chemical, physical, or microbiological analyses are performed. Lighting must be broad, uniform, and high in CRI to prevent errors.

Recommended lighting: Recessed LED panel mounted on the ceiling, natural white color (4000-5000K), CRI ≥ 90, illumination of at least 800 Lux.

Sensory Evaluation Zone — Accurate color representation

Used for visually checking product color, shine, clarity, and texture—for items like lipstick, foundation, or serum.

Recommended lighting: Specialized color viewing lamp with CRI ≥ 95, adjustable beam angle, simulating daylight (~5000K).

Sample Preparation Zone — Balanced and economical lighting

Area for sample mixing, dilution, or tool preparation—not requiring high sensory accuracy.

Recommended lighting: T8 LED tube fixtures, easy to replace, neutral white light (4000-4500K), illumination around 600-700 Lux.

QC Office Area — Comfortable for extended tasks

Intended for data entry, report writing, or procedural work. Lighting should be gentle, non-glaring, and adjustable to reduce eye fatigue.

Recommended lighting: Anti-glare LED fixtures with dimmer functionality, using warm or neutral light as per workspace design.

6. About Lighting in Cosmetic QC Rooms

Can standard LED lighting with CRI < 80 be used in a QC environment?

Not recommended. A CRI below 80 fails to accurately reproduce cosmetic product colors—especially for colored products like lipsticks, blush, or foundations. Misleading visual assessment results may arise.

Recommendation: Use lighting with CRI ≥ 90 in general inspection areas, and CRI ≥ 95 in color-critical zones.

Is there an ISO standard for lighting in cosmetic QC rooms?

Yes. ISO 22716—Good Manufacturing Practice (GMP) guidelines for cosmetics—stipulates clear requirements for lighting in production and quality control zones:

- Sufficiency, uniformity, and flicker-free lighting

- Fixtures installed to prevent shadows and glare

- Ease of cleaning, and protection from dust and insects

Additionally, inspectors may request documentation of lux-level measurements (Lux Test Report) as part of GMP compliance.

Is periodic illuminance testing required?

Yes. Quality management systems recommend:

- Conducting illuminance checks every six months using a lux meter

- Reassessing after maintenance, lighting replacement, or layout changes

- Storing records for internal audits and third-party (GMP, ISO) evaluations

Recommended Illuminance: 500-1000 Lux, depending on the QC area.

7. Need Expert Guidance for Lighting Your Cosmetic QC Room?

Whether you're designing a new QC facility or upgrading an existing lighting system, choosing the right fixtures—meeting technical specifications and ISO/GMP requirements—is essential for:

- Accurate sensory assessment

- Unbiased evaluation of color, texture, and clarity

- Success in ISO 22716 inspections and quality audits

VCR - Your Comprehensive Cleanroom Lighting Partner

- Supplies specialized LED lighting for cosmetic QC rooms (high CRI, dust- and glare-resistant)

- Provides free consultation tailored to functional zones: sample analysis, sensory, administrative

- Supports illuminance testing, documentation, and optical certification

Contact us now to receive detailed advice and a cost estimate:

Hotline: 090.123.9008

Email: [email protected]

Website: https://phongsachmypham.com/

Diep VCR

Vietnam Cleanroom (VCR) là một doanh nghiệp hàng đầu tại Việt Nam chuyên cung cấp thiết bị và giải pháp phòng sạch. Với hơn 10 năm kinh nghiệm phục vụ các dự án phòng sạch đạt tiêu chuẩn GMP, VCR tự hào mang đến các thiết bị kỹ thuật cao như: đồng hồ chênh áp, khóa liên động, đèn phòng sạch, Pass Box, FFU (Fan Filter Unit), buồng cân, HEPA Box, Air Shower, cửa thép phòng sạch, tủ cách ly (ISOLATOR), và nhiều loại phụ kiện chuyên dụng khác

Không chỉ là nhà cung cấp thiết bị, VCR còn là đơn vị phân phối độc quyền các sản phẩm từ các thương hiệu quốc tế như LENGE và BLOCK Technical, đồng thời cung cấp các giải pháp phòng sạch toàn diện cho các lĩnh vực như dược phẩm, điện tử, y tế, thực phẩm và mỹ phẩm. VCR có đội ngũ chuyên gia giàu kinh nghiệm, kiến thức chuyên sâu về phòng sạch, hỗ trợ tư vấn về tiêu chuẩn, thiết kế, thi công và vận hành phòng sạch theo chuẩn ISO, GMP, HACCP, ISO 14644

VCR hướng đến trở thành thương hiệu quốc dân trong ngành phòng sạch, với mạng lưới cung ứng rộng khắp, VCR có các văn phòng tại Hà Nội, TP. HCM, đáp ứng mọi yêu cầu từ xây dựng đến nâng cấp môi trường sản xuất đạt chuẩn

Email: [email protected]

Điện thoại: (+84) 901239008

Địa chỉ:

VP Hà Nội: 9/675 Lạc Long Quân, P. Xuân La, Q. Tây Hồ, TP. Hà Nội

VP Hồ Chí Minh: 15/42 Phan Huy Ích, P.15, Q. Tân Bình, TP.HCM

Hãy liên hệ với VCR để tìm hiểu thêm về lĩnh vực phòng sạch hiệu quả nhất nhé!